ALCO 244 and 251 Diesel Engines

| Bore | Stroke | Cyl. Disp | Rated RPM | Idle RPM | Comp. Ratio | Cyl. scavenging |

|---|---|---|---|---|---|---|

| 9" | 10.5" | 668 cu. in. | 1000 | 350 | 13:1 | Turbocharger |

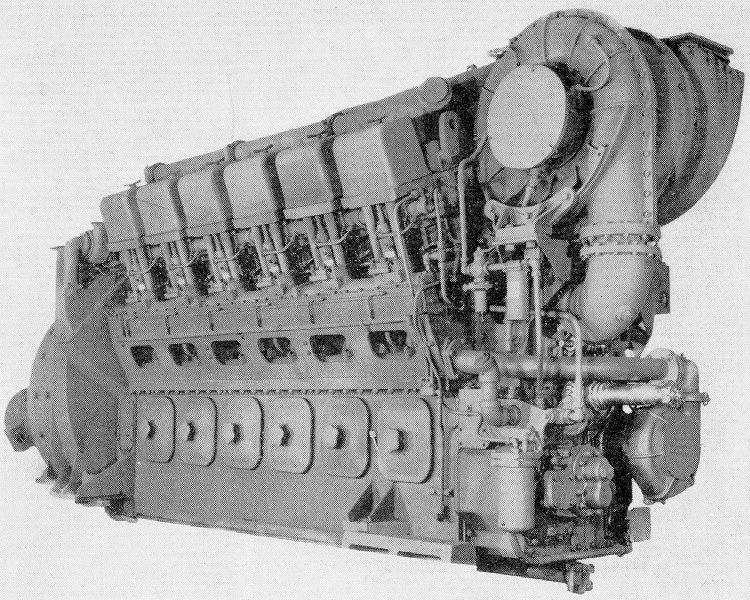

ALCo Model 244 V-12 |

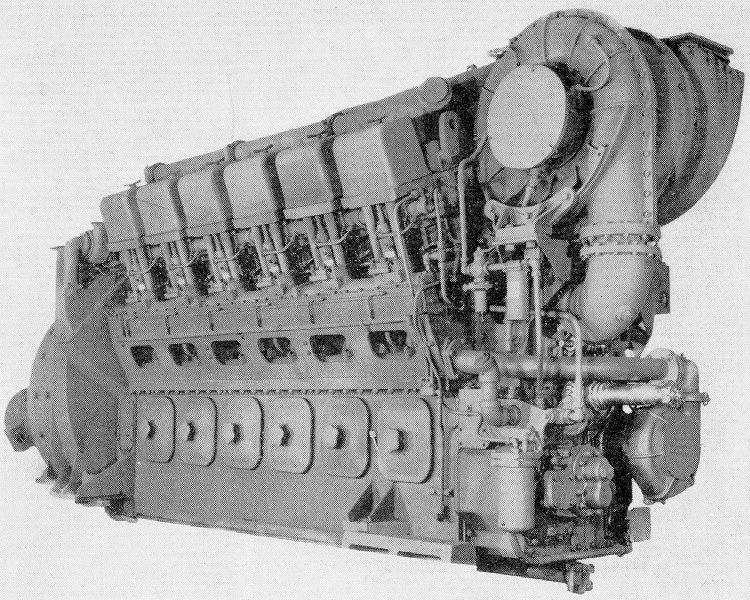

ALCo Model 251 V-12 |

| Bore | Stroke | Cyl. Disp | Rated RPM | Idle RPM | Comp. Ratio | Cyl. scavenging |

|---|---|---|---|---|---|---|

| 9" | 10.5" | 668 cu. in. | 1000 | 350 | 13:1 | Turbocharger |

ALCo Model 244 V-12 |

ALCo Model 251 V-12 |

The following is from an ALCO 244 operation manual.The locomotive is powered by a 12 cylinder, V type 9" X 10- 1/2", single acting, turbosupercharged, 1600 HP Diesel engine of four stroke cycle having an open combustion chamber with solid fuel injection. The engine speed is 350 RPM idle to 1000 RPM full speed and governed by an electro-hydraulic governor.

Each cylinder requires two engine revolutions or four strokes of the piston to complete one working cycle. One complete piston working cycle is as follows: first, air is blown into the cylinder on the down or intake stroke; then on the compression stroke this air is compressed by the rising piston with a large increase in temperature. Just before the end of the compression stroke, fuel is injected into the cylinder where it is ignited by the heat of the compressed air. The resulting combustion increases the cylinder pressure and on the third or power stroke, this gas pressure forces the piston down. On the fourth or exhaust stroke, the burnt gases are expelled by the piston traveling upwards and by scavenging action of pressurized inlet air made possible by a long intake and exhaust valve overlap.

The Diesel engine has an all welded steel frame. Full pressure lubrication to all parts is provided. A closed cooling system is used; the cooling water flows successively through the engine, the radiators and the lubricating oil cooler and is circulated by an engine driven centrifugal pump. Lubricating oil is cooled by the water in the heat exchanger and the water by fan cooled radiators. Thermostatically controlled radiator shutters, fan, and on late model units a by-pass valve, maintain desired engine temperature automatically.

Back to the Diesel Roster Table

Back to the Diesel Roster Table